Talking about it is one thing.

Doing it is another thing entirely.

Sure, there's plenty of brands in the UK who can tell you about making glasses frames. But, there's very few who actually do it themselves.

A sobering prospect considering the UK used to manufacture 5 million spectacle frames a year.

As the only glasses frame manufacturers in Scotland, we wanted to share with you how glasses frames are made.

Oh yes, our glasses are handmade and they’re handmade right here in the UK.

From sheet to shop, here’s a list of the processes we use to make our core collection and secret collections of spectacles and sunglasses.

How are glasses made step by step?

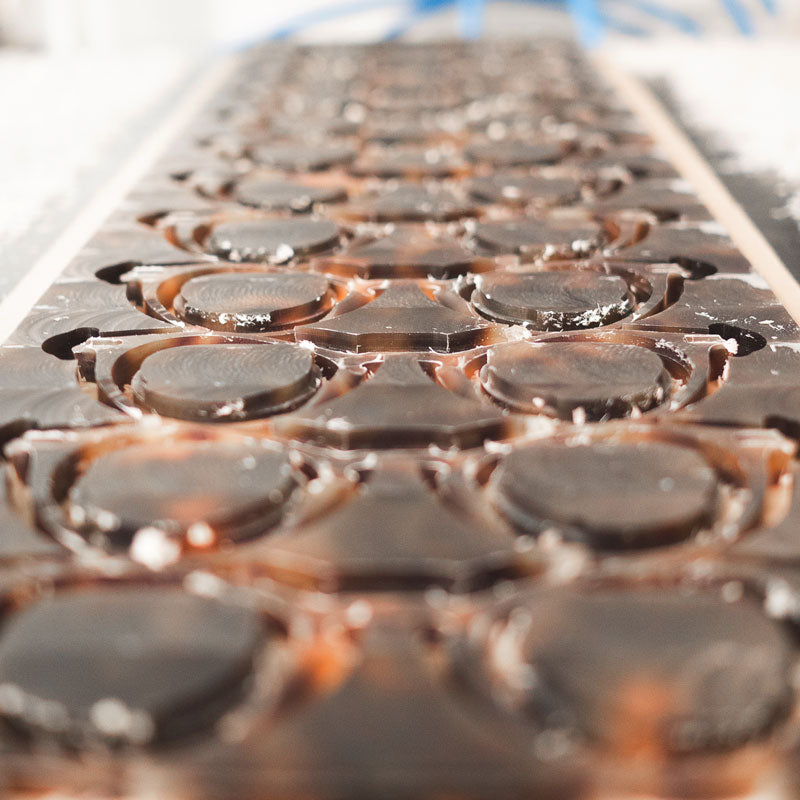

ACETATE CUTTING

So, how are glasses made?

At Banton Frameworks, we believe the best place to start is with the best materials. That's why every month, we receive a delivery of the best acetate from Europe’s best supplier.

The large acetate sheets can barely fit through our workshop doors, so in the Summer months, we cut them outside using our table saw.

In winter, we still use our table saw but there's a lot of sweeping afterwards...

MACHINING

Our frames designs are timeless and quiet, but making them is loud.

Outside our workshop, you'll often hear the deafening buzz of our in-house CNC machine.

Ear defenders definitely on, the frame fronts are precision cut from strips of thick acetate sections.

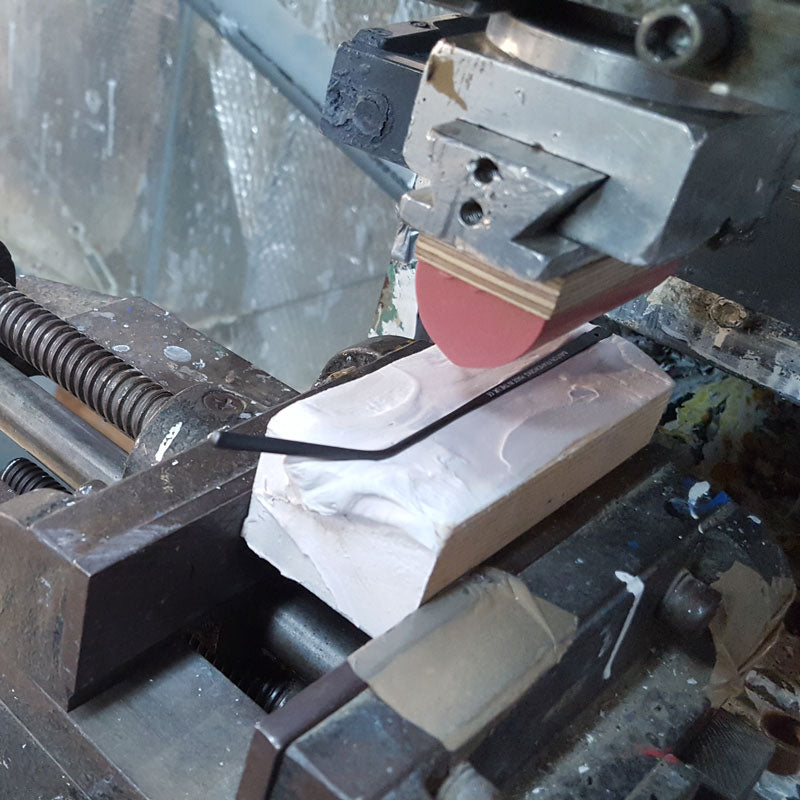

CUTTING

Confidence and commitment; the required attributes to cut the lens grooves in our frames.

This involves using a custom built table and cutting tool to cut a small channel in the inner periphery of the lens hole. Without this groove, the frame can't be fitted with lenses.

COUNTER BORING

Consistency. Consistency. Consistency.

This fine process requires a handheld-drill to create four small recesses in the acetate frame front.

These four holes are for our small solid steel rivets. If the recess is too deep, the frame is ruined. Too shallow, the rivets stick out and catch on your cardigan.

RIVETING

Think bridges. Think spitfire planes.

Rivets hold together the strongest of structures. Our glasses are no exception.

Using a 1976 pneumatic riveting machine, our five tenon hinges are permanently fastened to our frames and temples.

This process is precise, traditional and reliable. Like our mission, these hinges are fixed, solid.

CURVING

Curves are always nice, especially in the right places.

Our frame fronts are heated in an oven before we curve them using our self-built pneumatic press. At the correct temperature, your frame is swiftly removed from the oven and placed under our press. A pneumatic piston is deployed, descending to curve your frame using a precision machined mould below.

These curves make your frame comfortable to wear and allows lenses to fit more easily. To keep its shape, your frame is then plunged into cold water.

TUMBLE POLISHING

On your local beach, you'll often find smooth pebbles.

Over time, natural abrasion between the sand and small stones all rub against one another to gradually become smoother. Tumbling our frames has the same result. No sand though.

We use this process to remove marks and scratches from the previous stage of machine cutting our frames. Mesmerising to watch, we put our frames inside large barrels with what is known as ‘tumbling media’.

Very simply, the frames and media are thrown around inside the barrel via rotation to create friction and polishing.

MEDIA BLASTING

During the tumbling process, polishing wax works its way into the lens grooves and crevices.

It's a necessary process but it can take a while to get your frame clean again. Listening to the latest audiobook or podcast, your frame is cleaned inside our blasting unit where it's lovingly brought back to life.

TEMPLE MACHINING AND PAD PRINTING

Machined from stainless steel, our uni-piece temples are a seamless, flowing form. Tapered towards each tip, a ball-end acts as a counterweight to the frame front.

Made from a singular part, the steel is PVD coated in a robust colour finish.

After coating, the temples are professionally pad printed on the inside edge with our company information.

This method yields very small, accurate lettering on the inside of our uni-piece temples.

ASSEMBLY

Oh boy, this is the good bit. Your frame is ready for assembly.

Small 1mm dowel screws are used to join the frame front to the temples via our riveted hinges. We use five tenon hinges, which yield a high quality, stable hinge action.

Opening and closing the hinges is a truly tactile experience, one you can savour when you unpack your new frame.

LENS FITTING

Sunglasses or spectacles, lenses can now be fitted.

Using an optical frame heater, the acetate is gently warmed to make it easier to fit the sun lenses into the lens grooves.

Lenses can be single vision, reading, bifocal or varifocal depending on your prescription. To see what our lens partner Lensology can offer you click here.

PACKING

Our luxurious packaging carton is constructed from die cut, high gsm paper from a specialist mill in the North East of Scotland.

Inside and out, text and logo are foil blocked in a matt silver finish. A bespoke black silicone band envelops the container's exterior to seal the contents within.

This band eradicates the need for any adhesives whilst yielding a tactile unboxing experience.

Shop men's glasses

Shop women's glasses

Where are glasses manufactured?

To an extent, most, if not all glasses frame are handmade

The detail is where they’re handmade.

Today, the majority of eyewear is predominantly mass-produced in Italy, France, Japan and China using a combination of manual skill, semi-automatic and automatic production processes.

Recently, direct-to-consumer brands have begun to grow, selling acetate frames at very low price-points. The processes used to make these glasses frames are affordably labour intensive from the lower costs of overseas manual work.

How long do glasses take to be made?

The time to make a pair of spectacles or sunglasses varies on the volume of production.

Bespoke frames can take several weeks to make, whilst mass produced ones can be made in less than 5 days.

Bespoke glasses can take several days to take it through each of the necessary processes. Often, these are done at a craft-based volume which usually consists of labour-intensive processes such as hand-cutting, hand-sanding, tumble polishing, hand-riveting and hand-assembling.

The time to do this can take up to 3 weeks or more depending on the intricacy and design of the spectacle frame.

Mass produced glasses are much quicker and involves batch production. Numerous glasses frames and temples (arms) are processed at once using semi-automated or even fully automated production processes.

The spectacles and components are taken through these stages more quickly and more consistently with less human intervention.

How were glasses made?

The earliest glasses frames were thought to have been made at the turn of the 12th century from naturally abundant materials such as bone, ivory, leather and wood.

Back then, these natural materials would have been hand-carved to accept the very basic and round lenses of that era. These glasses were usually made of two separate lens-holder, similar to two magnifying glasses joined together.

In more recent iterations, spectacles and sunglasses began to benefit from material developments such as polymers. In the mid-1900’s bio-plastics such as cellulose acetate were becoming more popular resulting from the post-war scarcity of natural materials.

The college of optometrists has put together an informative article about the history of the earliest spectacle frames which you can read here.

What is the best material for eyeglass lenses?

Today, the preferred material for spectacle-lenses is high-density plastic.

Although glass provides the best optical quality, it has been predominantly outdated by several different types of plastic used to make glasses lenses.

These include composite, standard plastic, mid-index plastic, high-index plastic, polycarbonate and high-definition plastic.

You can read about these in more detail via the article by The Vision Council.

How are prescription sunglasses made?

The eyeglass lens manufacturing process for prescription sunglasses is carried out using the same lenses for spectacle frames but with a UV protective coating known as a “tint.”

Prior to cutting and edging the lens, the UV/protective coating is applied by dipping it into a bath containing the liquid tint. Different colours of tint can be applied to the lens which generally consists of brown, green, blue or grey.

Gradient tints can be achieved by from inverse dip-times in the bath. Upside-down, the top of the lens is immersed for longer than the lower region of the lens to create the tinted gradient.

For consistency, both lenses are dipped together which can be assisted with the aid of a dipping-arm machine.